|

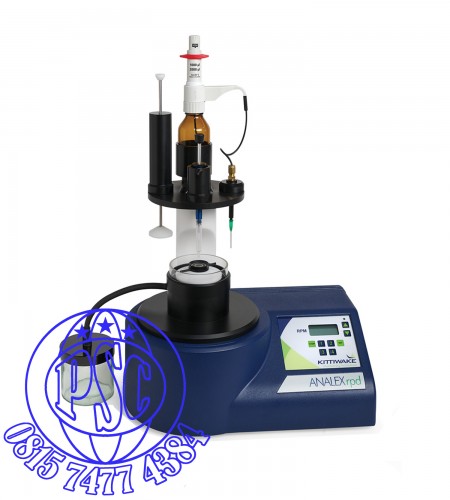

ANALEX rpd - metallic Wear Particle Depositor |

|

|

Product Code |

FG-K19026-KW |

|

A high ANALEX or Spectrographic wear metals reading often triggers a more in depth analysis. The * ( Rotary Particle Ferrograph ) offers a rapid and simple method of debris separation and particle size analysis. A measured volume of sample is applied to a rotating glass substrate. Debris is graded and deposited radially as three concentric rings by the combined effects of rotational, magnetic and gravitational forces. "Ferrography" may be divided into three techniques : |

|

|

Analytical ferrography ( AF ) - grades and separates wear debris ( particles of varying sizes ) from used or in-service oils by magnetic methods, producing glass slides for subsequent examination by microscopy. Preparation time per sample is about 20 minutes. |

|

|

Direct reading ferrography ( DRF ) - separates the debris into small and large particles and gives a quantitative measurement by a photometric method. Analysis time per oil sample is around 10 minutes. |

|

|

Rotary Particle Deposition ( RPD ) - using gravitational and centrifugal separation of a sample under a solvent cleaning flow. Analysis time per sample is around 6 minutes. |

|

|

Combined magnetic and centrifugal separation is faster than both the AF and DRF techniques, presenting a microscopy slide in around 6 minutes. The does not require the sample to be diluted and does not suffer from interference due to carbonaceous material in the sample. Removal of the lubricant by solvent washing and drying gives a stable well-separated deposit pattern ready for examination by optical or electron microscope. The 'Guide to Wear Particle Recognition', supplied with the , indicates the type of wear showing distinctive features and composition of typical wear debris. The separated debris can also be measured quantitatively by placing the substrate in an ANALEX PQ Ferrous Debris Monitor. Features cover : |

|

|

Simple method of wear debris separation, enabling you to effectively analyse the results of your oil sample |

|

|

An uncontaminated wear debris sample is produced - carbonaceous material is removed |

|

|

Excellent particle separation - deposition path length is equivalent to a linear 160 mm, with a wide particle size range - typically 1 to 2000 microns |

|

|

Supplied complete with a comprehensive "Guide to Wear Particle Recognition" |

|

|

The separated debris can also be measured quantitatively by placing the substrate in an Analex PQ Ferrous Debris Monitor |

|

|

Specifications |

|

|

Rotational Speed |

30 - 200 rpm ( 4 preset speeds ) |

|

Operating Temp. Range |

10°C to 30°C |

|

DC Power Input |

15 V DC |

|

AC Power Input to DC Supply |

100 - 240 V AC |

|

Display |

Alphanumeric LCD |

|

Dimensions |

360 mm x 220 mm x 500 mm |

|

Weight |

4.5 kg |

|

Ordering Information |

|

|

Part Number |

Description |

|

FG-K19026-KW |

ANALEX rpd Rotary Particle Depositor |

DKI Jakarta - Jakarta Barat

.png)